Keeping large trucks and heavy vehicles compliant in remote or high-output industrial operations across Australia and New Zealand is a growing challenge. Transporting vehicles to fixed inspection sites results in costly downtime, logistical complications, and unnecessary wear.

The Ryme Worldwide Universal Mobile Container, available through EquipSpecs, offers a smarter and more efficient approach to compliance testing for both light and heavy vehicles.

This self-contained, mobile inspection unit is specifically designed for on-site vehicle inspections—minimising downtime and eliminating the need to transport trucks long distances to fixed testing centres. Whether you manage a fleet in the Pilbara, operate in the Bowen Basin, or service rural areas across New Zealand, bringing inspection capability directly to your site gives you greater control over testing schedules and delivers long-term cost savings.

What’s Inside?

The container is divided into three functional zones:

- Administrative Area – A built-in office space to complete inspection documentation and manage compliance procedures.

- Inspection Area – Located in the centre of the unit, this section houses the full suite of testing equipment for brakes, suspension, lighting, emissions, and noise levels.

- Technical Area – Contains the power supply, including the generator and electrical control panels, which distribute power to the entire unit.

To accommodate large commercial and industrial vehicles, the container features a lifting roof and extendable flaps, providing up to 4.2 metres of clearance. With no need for fixed infrastructure, the unit can be deployed on-site to run full compliance checks and return vehicles to service faster.

📹 Watch the mobile unit in action on YouTube

🌐 View Ryme Worldwide’s official mobile unit page

Inside the Inspection Area of the Ryme Worldwide Universal Mobile Container

The following systems are recommended by Ryme Worldwide for inclusion in the Universal Mobile Container.

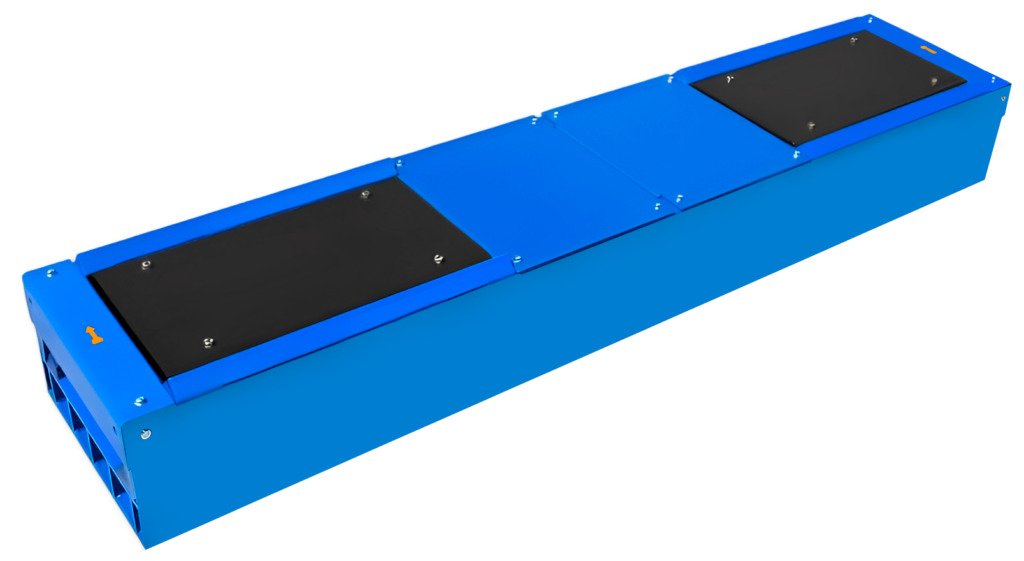

ALU Step Aligner

Designed to perform an efficient verification of the steering axle geometry of vehicles up to 4T.

- Test Speed: 5-10 km/h

- Up to three forms of measurement display

- Memorisation of two axles

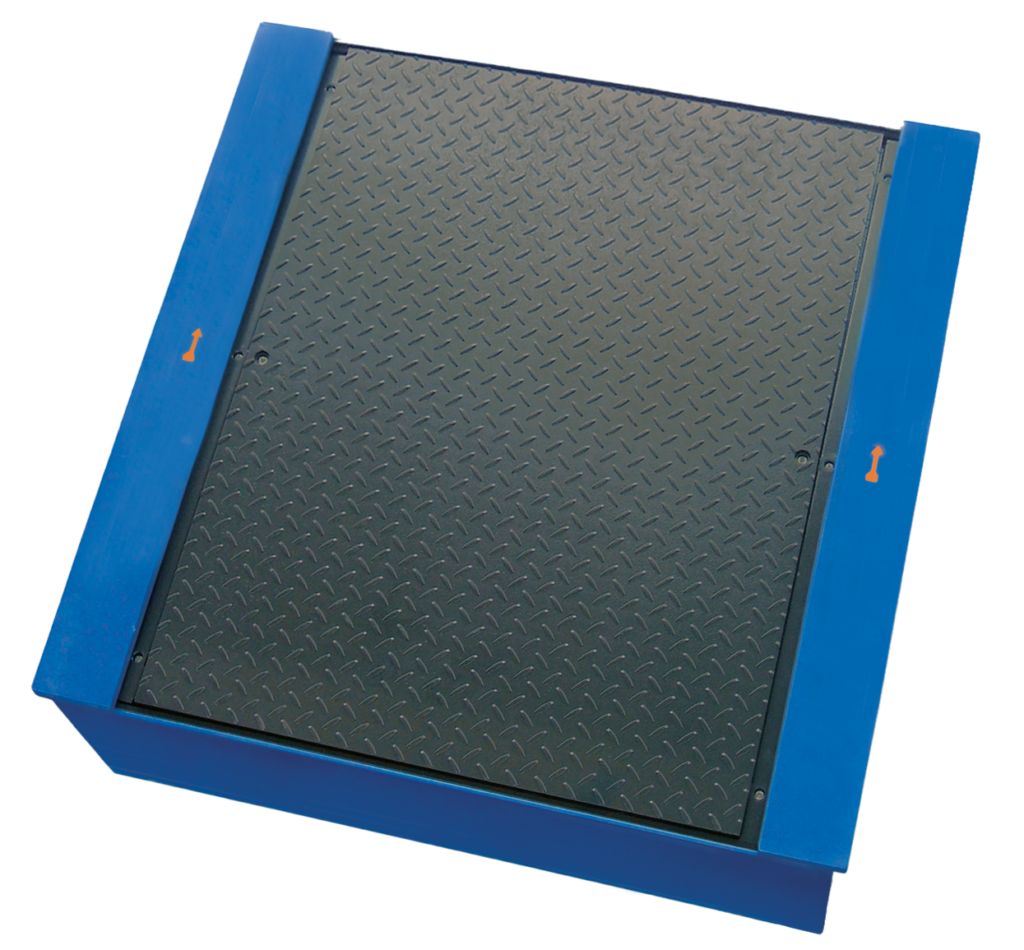

BSU Suspension Bench

Designed for fast and efficient analysis of the suspension condition of vehicles up to 4T per axle.

- Max. axle load per axle at passage: 16T

- Maximum track width: 2.120mm

- Minimum track width: 825mm

🔗 More about the BSU Suspension Bench

Universal Roller Brake Tester FRU P

Performs a complete assessment of the condition of the braking system of a light of heavy vehicle.

- Max. load per axle at passage: 20T

- Engine: 2 x 11 kW

- Specially designed equipment for mobile inspection units

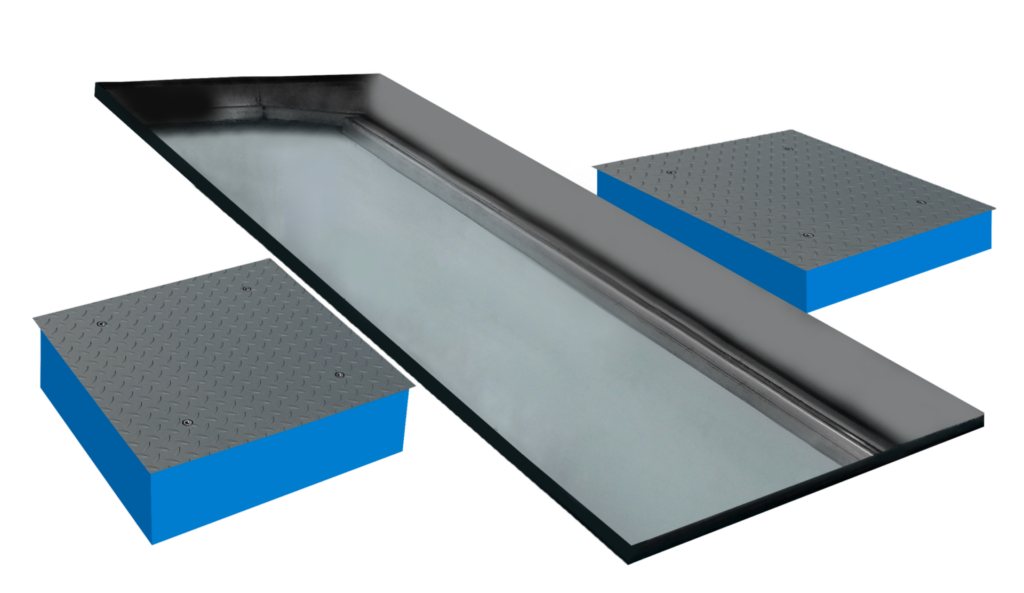

DHU Total Slack Detector

Checks the condition of the vehicle axles and their components.

- Makes it possible to observe the possible wear and resulting play in vehicles up to 18 T

- Engine: 2.2 kW

- Detector with two four-motion plates

🔗 See more on the DHU Total here

Gas Analyzer + Opacimeter – RY 4000 AGH

A device for the detection of ignition and injection problems, as well as for the improvement of fuel consumption.

- Integrated gas analyser + opacimeter

- Up to five gases (NOx optional)

- Operating temperature form -10 to 55⁰C

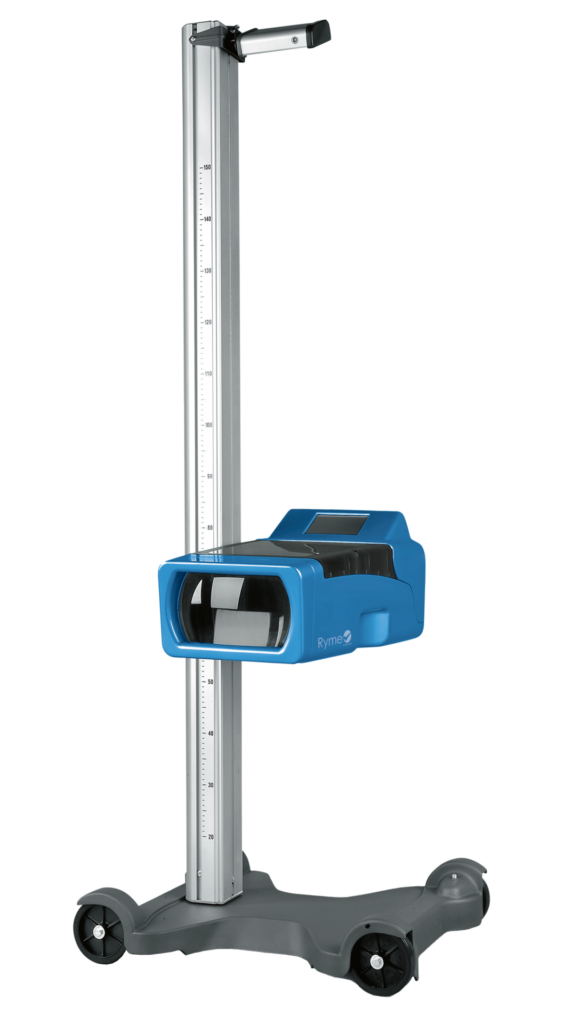

Digital Headlight Tester – RY RM

Electronic light analyser equipped with a camera for a complete headlight analysis.

- Digital operation

- Graphical LCD display for precision and simplicity

- Halogen, Xenon, Dipped beam, High beam, and Fog light.

Class 2 integrative sound level meter

Carries out measurements and completes checks and calculations indicated in standards to allow the final result to be obtained on site.

- Bluetooth Connectivity

- Backlit LCD display

- Removable pre-amplifier for both vehicle and machine noise measurements

🔗 Download the SC-202 brochure

Build a Mobile Testing Solution Around Your Needs

The equipment outlined above represents Ryme Worldwide’s recommended configuration for a fully equipped Universal Mobile Container. However, each unit can be tailored to your operational environment, compliance obligations, and testing workflow.

Whether you’re managing a mine-site fleet, servicing local government contracts, or expanding capacity in a regional workshop, EquipSpecs will work closely with you to design a mobile vehicle testing solution that delivers long-term value.

Our team has extensive experience supporting compliance operations across Australia and New Zealand. We’ll help you assess your site conditions, select the right equipment mix, and ensure your unit aligns with both regulatory standards and operational requirements.

📩 Contact the EquipSpecs team today to discuss how the Universal Mobile Container could streamline your compliance operations.

sales@equipspecs.com.au | sales@equipspecs.co.nz