EquipSpecs NZ is proud to supply high-quality Comec workshop machines, engineered for precision, reliability, and efficiency. As part of our commitment to delivering complete turnkey workshop solutions, the Comec range complements our wider workshop equipment offering — including our full lineup of truck brake testers, roller brake testers for light vehicles, and prefabricated steel inspection pits.

About Comec

With over 50 years of experience, Comec is a global leader in precision workshop machinery for the automotive and heavy vehicle industry. Designed and manufactured in Italy, Comec equipment combines advanced engineering, innovation, and strict quality control to deliver long-lasting performance. Each machine reflects Comec’s commitment to continuous improvement, safety, and accuracy — values that have made them trusted by professional workshops worldwide.

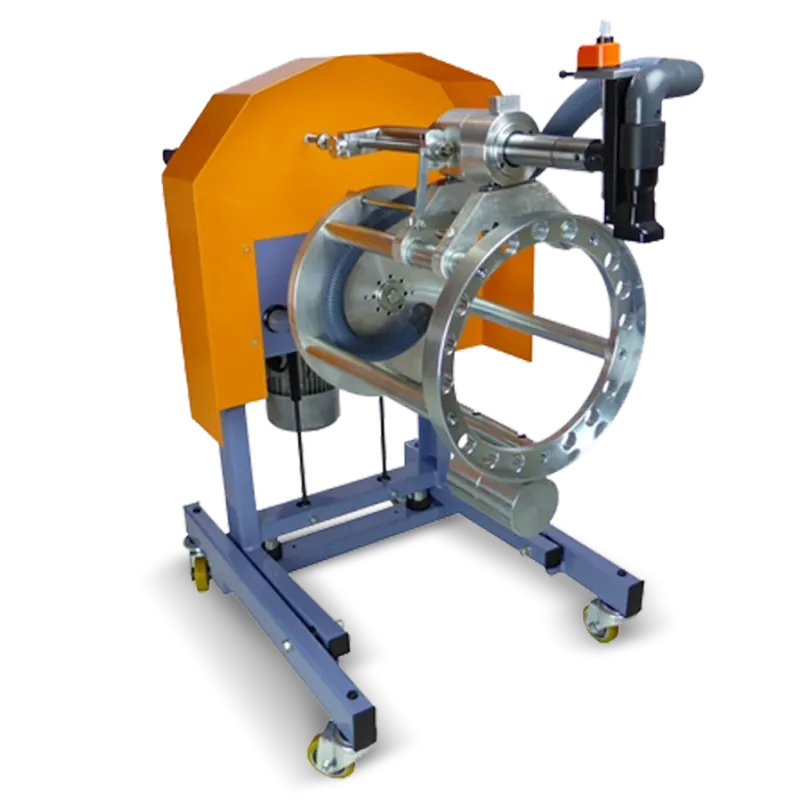

On-the-Truck Brake Shoe Lathe

Overview / Key Features

- On-the-truck operation:

Machining is operated directly on the gear unit hub axle or on conventional axles (using suitable accessories), reducing downtime. - Patented self-aligning carriage:

Height-adjustable, tilting, and self-aligning design for quick, accurate setup on a wide range of heavy-duty vehicles. - Powerful performance and precision:

High-speed 90 rpm rotation and sequential 0.6 mm/rev feed deliver smooth surface finishing and exceptional concentricity precision, even under demanding conditions. - Durable, heavy-duty design:

Equipped with a 1.8 kW gearmotor and soft-start control for reliable operation under extreme loads — including multi-differential systems and cold environments.

| Specification | Value |

|---|---|

| Rotation Speed | 90 rpm |

| Sequential Feed | 0.6 mm/rev |

| Min turning diameter | 230 mm |

| Max turning diameter | 480 mm |

| Max brake shoe depth | 290 mm |

| Motor Power | 2.5 Hp (1.8 kW) |

| Dimensions (L × W × H) | 670 × 950 × 1150 mm |

| Weight | 160kg |

Benefits

- Reduces workshop downtime

- Improves brake safety and performance

- Compact design suitable for NZ workshops

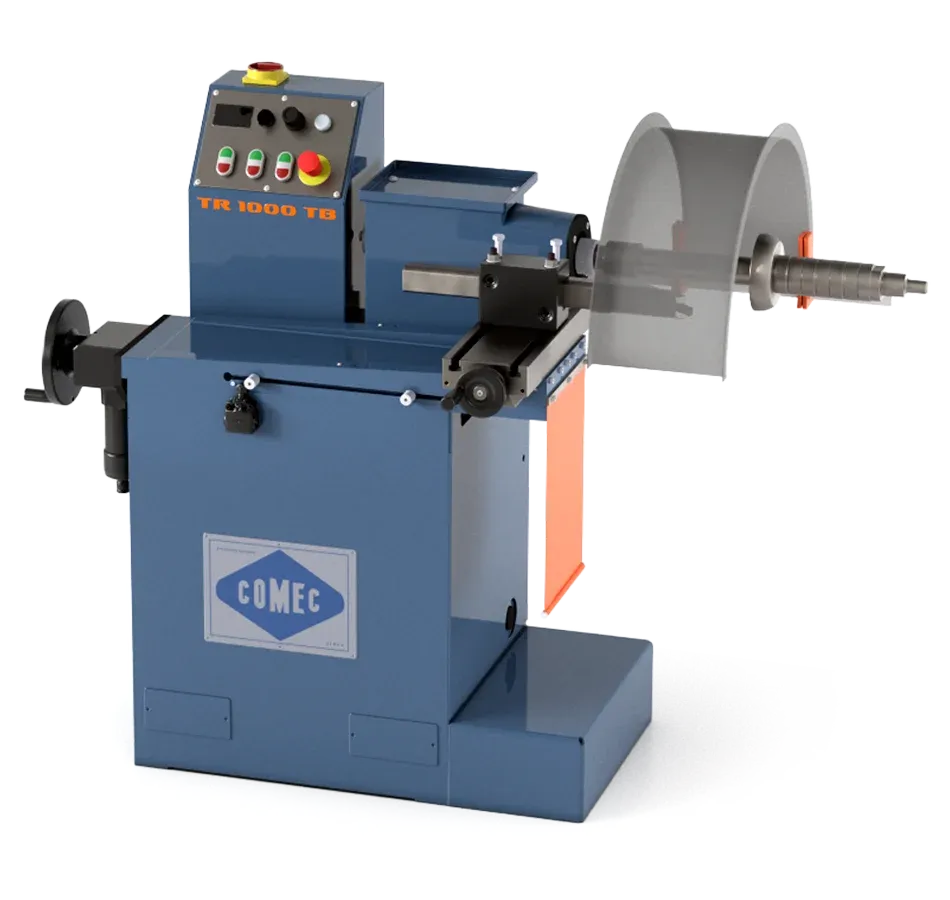

Heavy Duty Brake Drum Lathe

Overview / Key Features

- Professional brake drum reconditioning:

Ideal for cars and trucks, delivering precise and reliable machining for both discs and drums. - Durable cast iron construction:

Heavy-duty cast iron base, tables, and lathe unit box ensure structural solidity and long-lasting performance. - Intuitive controls:

User-friendly adjustments allow quick setup and precise operation, giving excellent accuracy and finishing. - Flexible optional accessories:

Supports additional tools like the shaft support arm for twin wheels or powered cross slide feed for disc turning, allowing customization for specific workshop needs.

| Specification | Value |

|---|---|

| Min-Max drum turning diameter | 150÷1170 mm |

| Mx disc turning diameter | 865 mm |

| Longitudinal table travel | 410 mm |

| Cross slide travel | 145 mm |

| Spindle rotation speed | 30÷120 rpm |

| Longitudinal table feed | 0÷30 mm/min |

| Cross slide feed (option) | 0÷30 mm/min |

| Spindle motor power | 1.5 kW |

| Table motor power | 0.07 kW |

| Dimensions (LxWxH) | 1970X1400X1470 mm |

| Weight | 655 kg |

Benefits

- Extends brake component life

- Ensures safe, reliable brake performance

- Simple installation and operation

Comec Product FAQs

Below are some of the most common questions about Comec workshop equipment. Learn more about the TR1000 Brake Disc and Drum Lathe and the TCE560 On-the-Truck Brake Shoe Lathe — both trusted for precision, performance, and long-term reliability in professional vehicle workshops across New Zealand.

Comec is an Italian manufacturer specialising in precision workshop machinery for the automotive and heavy vehicle industry. Their range includes brake lathes, testing equipment, and reconditioning tools trusted worldwide for reliability and build quality.

The Comec TCE560 is an on-the-truck brake shoe lathe designed to operate directly on the gear unit hub axle or by using suitable accessories on conventional axles (even with mounted internal bearing).

The TCE560 is suitable for trucks, buses, and heavy commercial vehicles. Its on-the-truck operation makes it ideal for workshops servicing fleet or transport vehicles where downtime needs to be minimised.

Key features include a soft-start electric device, precision machining system, adjustable carriage movement, and easy setup directly on the wheel hub. It is engineered for accuracy, repeatability, and operator safety in heavy-duty applications.

The Comec TR1000 is a professional lathe designed for drum reconditioning on cars, vans, and light commercial vehicles. It’s cast-iron structure and intuitive controls make it easy to use whilst ensuring accuracy and reliability.

The key features of the TR1000 are the structural solidity, granted by the wide use of cast iron for all components (base, tables and lathe unit box), and by its simple use. It can accommodate a wide range of disc and drum sizes, making it versatile for most workshops.

Yes. EquipSpecs is an authorised supplier of Comec workshop equipment in New Zealand, offering the TR1000 and TCE560 models with full local support, parts availability, and after-sales service.

Detailed technical specifications and brochures for both the TCE560 and TR1000 can be downloaded directly from the EquipSpecs NZ website on the Comec product page.

Yes. Comec provides official product demonstrations on YouTube, showing the TCE560 and TR1000 in action. These videos are also available to view on the EquipSpecs NZ website.

Ready to Upgrade your workshop?

EquipSpecs is your trusted supplier of Comec workshop equipment in New Zealand.

Contact our team today to discuss the TR1000 Brake Disc and Drum Lathe or the TCE560 On-the-Truck Brake Shoe Lathe, and find the right setup for your workshop.

📞 Call us: 021 477 646

📧 Email: sales@equipspecs.co.nz

📩 Or use our contact form to get in touch.